| HY-3021 Plastic Positive and Negative Thermoforming Machine |

塑料热成型机.jpg) |

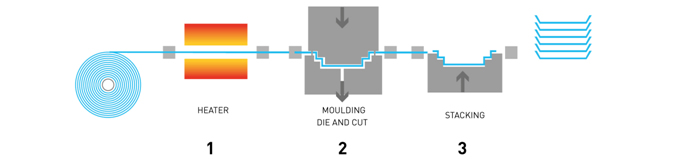

Production process

Brief Introduction

HY-3021 positive and negative(in-mould cutting) plastic thermoforming machine, with a new design concept and control system, is suitable for PP, APET, PVC, PLA, BOPS, PS plastic sheet rolls to produce all kinds of high transparent, high tensile turn-up and flat products, such as bowls, dishes, lids, fruit boxes, vegetable boxes, food boxes and plastic trays for wine, medicine, electronics, daily necessities.

Main Features

● Suitable for PP, APET, PVC, PLA, BOPS, PS;

● Feeding, forming, cutting, stacking are driven by servo motor;

● In-mould cutting ensuring consistent and accurate trim;

● Feeding, forming, in-mould cutting and stacking processing are complete production automatically;

● Mould with rapid change device,easy maintenance;

● Working station servo motor adjustment;

● Double selectable stacking systems;

Specifications

|

Model

|

HY-3021

|

|

Max Forming Area

|

540*760mm

|

|

Max. Sheet Width

|

1000mm

|

|

Max Forming Depth

|

Manipulator: 100mm

Downward stacking:120mm

|

|

Sheet Thickness Range

|

0.2-1.5 mm

|

|

Production Speed

|

600-1500 cycles/hr

|

|

Clamping force

|

100Ton

|

|

Heating Power

|

114 KW

|

|

Motor Power

|

33 KW

|

|

Air Pressure

|

0.7Mpa

|

|

Air Consumption

|

3000 liter/min

|

|

Water Consumption

|

70 liter/min

|

|

Power Supply

|

Tri-phase, AC 380±15V, 50HZ

|

|

Sheet Roll Dia.

|

1000mm

|

|

Weight

|

9000 Kg

|

|

Dimension(mm)

|

Main Machine

|

6500*2020*2400mm |

|

Feeder

|

1500*1420*1450mm |

|

|